Roles of Polyurethane (PU) and MS Polymer Sealants in Peru-Brazil Land Transport Infrastructure Projects

Aug 01,2025

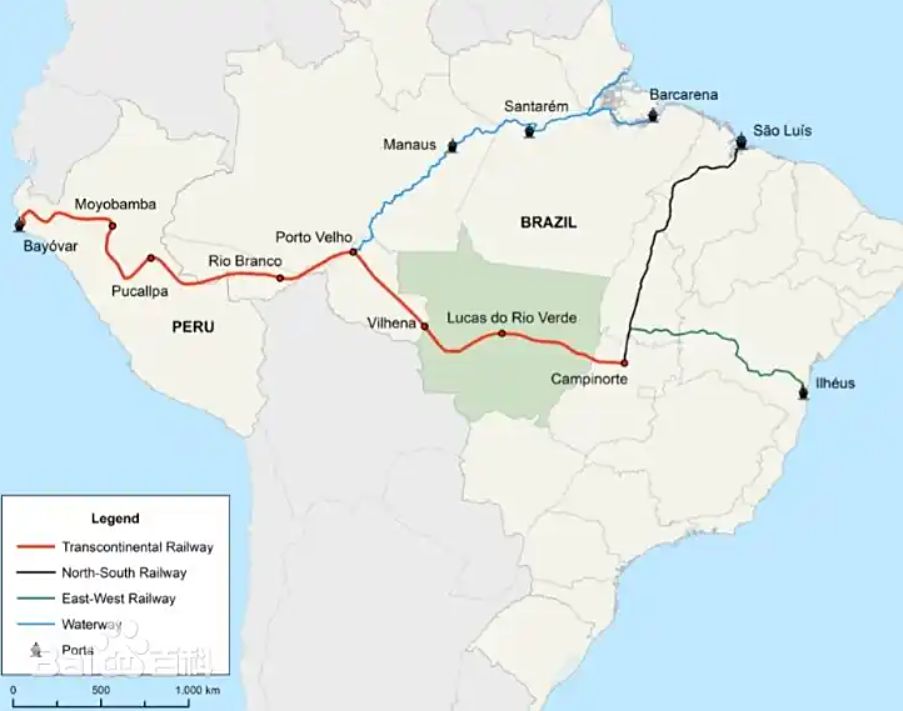

In the construction of land transport infrastructure (e.g., Interoceanic Highway, Bioceanic Railway) between Peru and Brazil, polyurethane (PU) and MS polymer (modified silane) sealants play critical roles due to their durability, flexibility, and resistance to harsh environmental conditions. Below are their key applications:

1. Bridges & Elevated Structures

Expansion Joint Sealing:

PU Sealants: Used for flexible sealing in bridge expansion joints, accommodating dynamic loads and thermal movement while preventing water/debris ingress.

MS Sealants: Superior weather resistance (UV, rain, temperature swings), ideal for Amazon rainforest and Andean mountain climates.

Concrete Joint Waterproofing:

Both sealants prevent water penetration into concrete gaps, protecting reinforcement steel from corrosion.

2. Tunnel Construction

Lining Joint Sealing:

MS Sealants: Excellent adhesion to wet surfaces, critical for humid tunnel environments.

PU Sealants: Absorb ground settlement stresses between tunnel segments.

Waterproof Membrane Edging:

Sealants fix waterproofing membranes at edges, ensuring long-term watertightness.

3. Road Pavement & Subgrade

Crack Repair:

PU Crack Fillers: Injected into asphalt/concrete cracks to restore integrity and prevent Amazonian rainwater erosion.

Drainage System Sealing:

MS Sealants: Seal culverts and drainage pipe joints to avoid leaks that weaken the roadbed.

4. Railway Applications (Bioceanic Railway)

Slab Track Joints:

PU Sealants: Absorb vibrations in concrete track slabs, enhancing stability.

Sleeper Fixation:

PU Elastomers: Used as ballast glue (e.g., PU-injected sleeper pads) to stabilize tracks on soft tropical soils.

5. Ancillary Structures

Noise Barriers & Guardrails:

PU Adhesives: Bond metal/concrete components with high shock resistance.

Signage Mounting:

MS Sealants: Secure traffic signs to concrete bases, resisting wind loads and UV degradation.

Project-Specific Challenges & Solutions

Amazon Rainforest:

MS sealants outperform in high humidity, while PU may fail if applied on wet surfaces.

Andes Mountain Range:

PU’s cold flexibility (-40°C) suits high-altitude zones, whereas MS handles extreme heat (+90°C) in lowland areas.

By strategically using PU and MS sealants, these infrastructure projects achieve enhanced durability, reduced maintenance, and improved safety across diverse terrains.

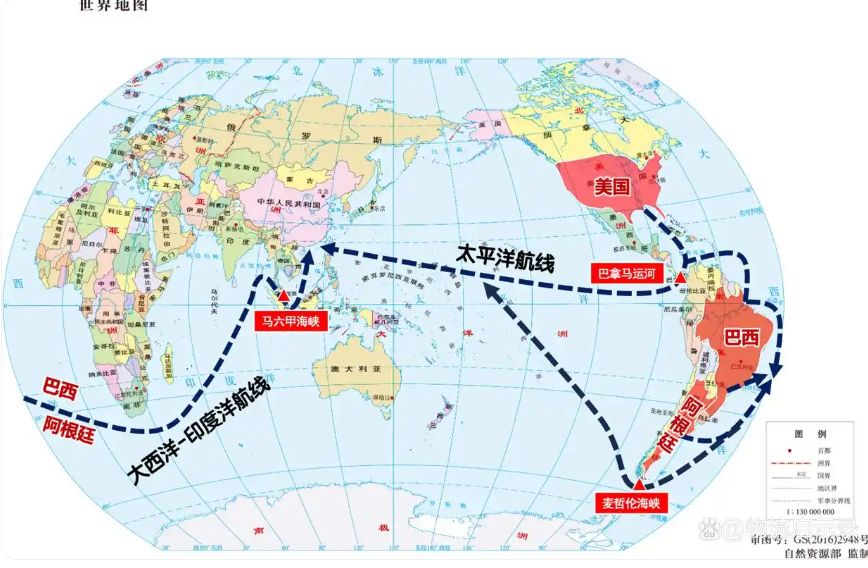

Once the "Two Oceans Railway" is completed, it will become the first continental bridge in history to cross South America. The hinterland of South America can be directly connected to the ports along the Pacific coast through this major artery. Transportation costs will be significantly reduced, time efficiency will be greatly improved, and it can also give rise to a number of inland port cities, fundamentally reshaping the industrial and economic geographical map of the South American continent.

PREVIOUS:

Others